Method

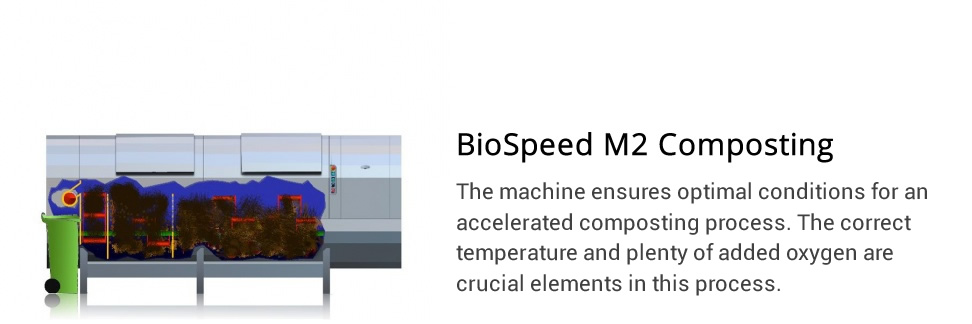

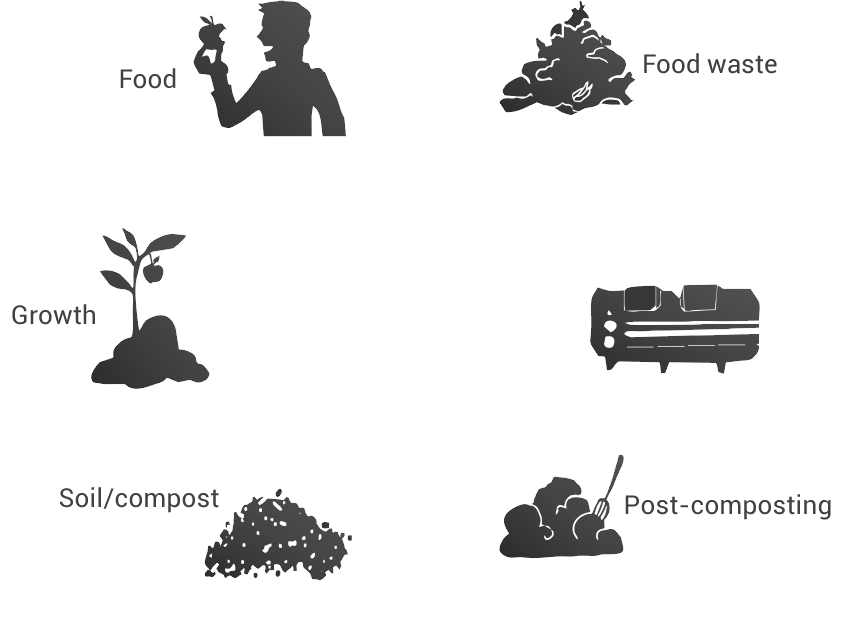

The BioSpeed composting process is based on a method that enables microbes to function under optimal conditions. All the microbes used in the BioSpeed system, including the cellulose-degrading ones, are advanced mesophilic and thermophilic microbes, i.e. they work at temperatures of up to 80 degrees Celsius (oC).

These parameters enable an accelerated and continuous decomposition of organic material into powder, providing high capacity in compact machines.

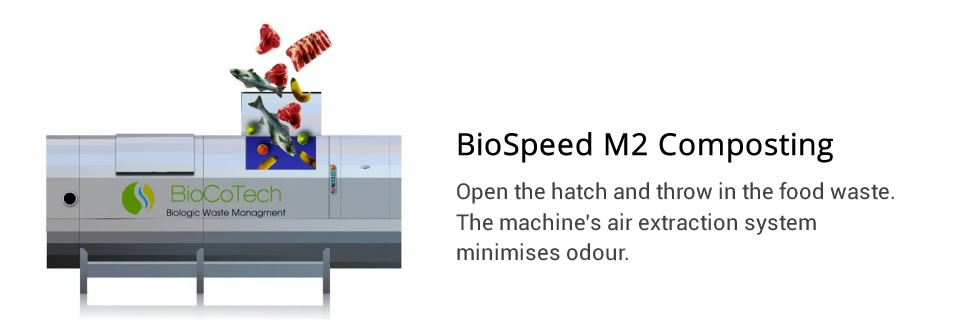

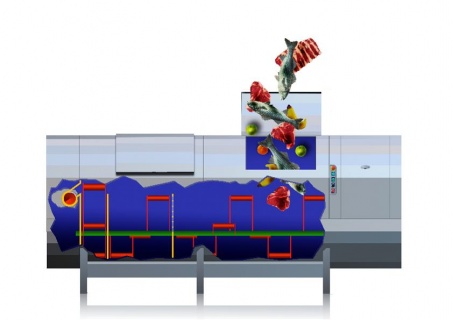

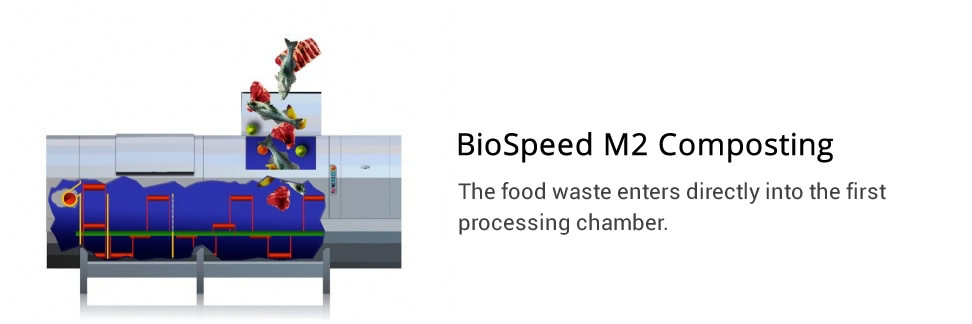

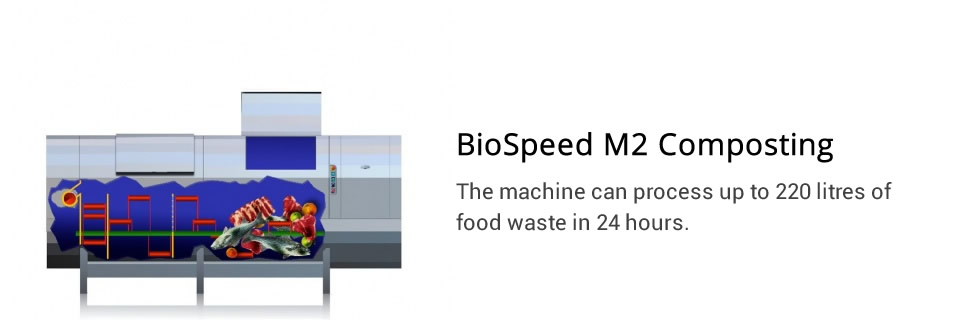

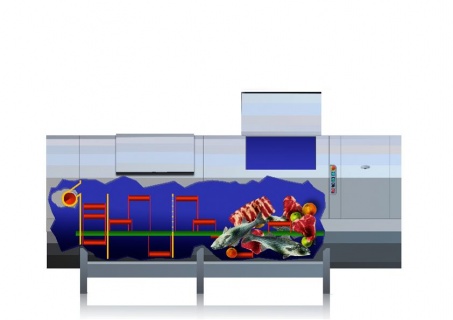

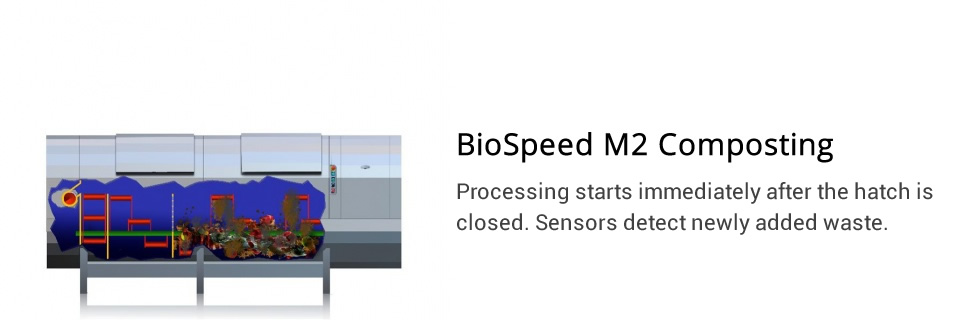

This is how a BioSpeed composting machine works:

- The food waste is emptied into a processing chamber, either directly or through a mincer.

- The machine processes and aerates the waste using an innovative mixing technique.

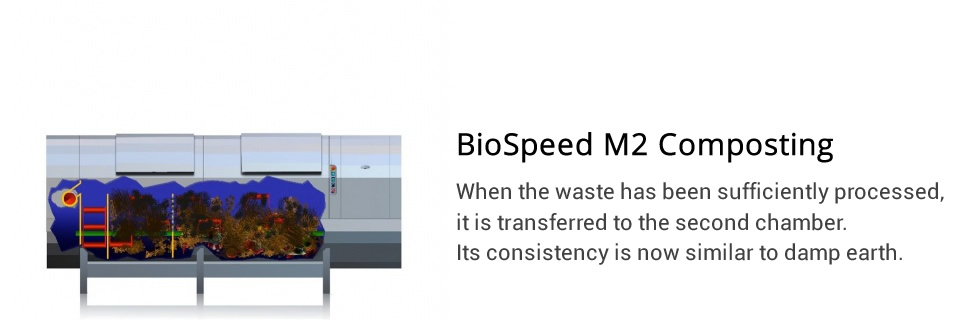

- In the course of 24-72 hours, microbes break down the waste into a compost powder that is automatically discharged from the processing chamber.

- The compost powder is hygienic and easy to empty.